You will never own an an electric car. You the current reader personally might, you might already even own one, but statistically we cannot replace every car currently on the road one-to-one with EVs and it’s all because of this stuff called Lithium.

Alongside silicon semiconductor fabrication and realising standardised containers make shipping really really cheap, Lithium-ion batteries are one of the miracle inventions that make our modern world possible. Despite having cheap computers by the 1970s and practical applications of radio even before the first world war, there were few serious attempts to combine the two technologies until commercially available Lithium-ion batteries started to hit the market in 1995.

The issue was simply Energy Density or how much power you can store in a given size and weight of battery. In 1990 the best you could get was about 50 Watthours-per-kilogram (Wh/kg). 50 Watthours (Wh) means 50 watts for 1 hour, or 25 watts for 2 hours, or 100 watts for 30 minutes. 50 Wh/kg was a significant improvement over Lead-acid batteries - largely unchanged for a century - which topped out around 30 Wh/kg. The very first Lithium-ion batteries produced by Sony in 1995 pushed this number to 80 Wh/kg, by 2007 when the iPhone was announced they’d reached 200 Wh/kg and today they’re closing in on 400 Wh/kg.

While computer performance and storage has advanced dramatically over the past 30 years, the evolution of mobile computing has been driven far more by this exponential improvement in battery technology.

Many in Britain still remember a time when the Milkman would come round every morning on an electric milk float. They weren’t fast and had minimal range, but it reminds us that the electric vehicles are not a modern idea. Infact early combustion engines were considered so inefficient and unreliable that until 1900 many suspected electric automobiles were the future of transporation, they just needed to make the batteries a little better, right?

The problem was physics. While the Lead-acid batteries of the 1890s couldn’t break 10 Wh/kg, a newly refined form of Oil that contained over 13,000 Wh/kg had just been developed. It was called Petrol. Any inventor looking to start a car company at the turn of 20th century could build an enormous tank of a vehicle with a 5 ton battery, or they could just put a little work into making those pesky internal combustion engines reliable and get the same energy in a 5 litre tank under the seat. Naturally early leaders like Fiat, Peugeot and Mercedes chose the latter.

Returning to the modern day this raises an obvious question: If the energy density of petrol is still so much higher than a modern Lithium-ion battery, how can electric vehicles be viable competitors? Simple, they cheat. No Battery Electric Vehicle (BEV) today is actually an apples-to-apples comparison to any Internal Combustion Engine (ICE) vehicle. They’re all making trade-offs, there’s no getting around the fact that 1 kg of petrol contains 30-35x the energy of a 1 kg battery. So what are those trade offs?

First they have a shorter range. Tesla has spent years working towards a golden target of 400 miles on a single charge, motivated by the 400-500 mile range of the luxury Saloons the Model S was first developed to compete with. As of a couple years ago they’ve finally achieved that, it’s an impressive feat, however ICE vehicles have gotten more efficient over those 15 years too. Cars like the BMW 5-series, the Peugeot 508 and the Volvo S60 are getting well over 1000 miles out of a tank under much more realistic driving conditions. 400 miles certainly seems enough given the average weekly mileage is 142 miles in the UK, but comparing a 2023 Tesla to a 2007 BMW or Volvo is cheating.

Second, electric drivetrains are innately more efficient. When you hit the accelerator every watt of energy goes into moving the vehicle forward, when you lift energy stops flowing instantly, and when you brake the vehicle recovers up to 70% of the energy through regenerative braking. Compare this to ICE drivetrains where you lose efficiency accelerating through sub-optimal power bands, you waste energy idling, and braking simply turns your forward momentum into toasty brake pads.

To understand the cumulative benefits of these factors we need only look at the rail industry. On track without electrical wires, Diesel-electric hybrid systems where the engine drives a generator that in turn powers electric motors have been standard in the rail industry since the 1950s for these very reasons. These locomotives are hybrids by pure necessity, attempting to drive the wheels directly from the engine just wouldn’t work, the torque varies too wildly, you’d be forever stalling out the engine and going through clutches like kitchen roll. We’ve had electric drivetrains far longer than we’ve had batteries with enough energy to power them, there’s just been too much stigma around hybrid cars. Hybrid buses for example are 20-25% more efficient than diesel buses. It’s not about smaller/lighter vehicles either, both of these trains are diesel-electric hybrids.

Regenerative braking is common in the rail industry too though it’s usually referred to as “dynamic braking”. Hybrid buses see an 11-22% increase in range with regenerative braking and the Siemens Velaro family of trains used on high speed rail networks across Europe regeneratively brake at almost 100% efficiency. Applying the brakes on one train can almost fully power another train a few miles away.

These may sounds like arguments for BEVs but they’re not. We could have gotten these benefits at any point in the last 50 years by switching to hybrid vehicles, the batteries were never needed to realise them.

Last we come to the biggest cheat of all, Weight. Going back to that Volvo S60 mentioned earlier, it has a curb weight of 1,614 kg. The Tesla Model S that breaks 400 miles has a curb weight of 2,261 kg, over half a ton heavier, more than a Range Rover. Again there’s no magic here, they just put a really big battery in there and it stores more energy, shocker. The extra weight makes them far more dangerous in a crash and it means that you’re wasting a lot of energy carrying an extra two-thirds-of-a-ton around with you everywhere you go. This might sound benign but it requires BEVs to have specially designed tires, stronger bodies and more stringement safety requirements which all increase cost, not to mention the staggering cost of the battery itself.

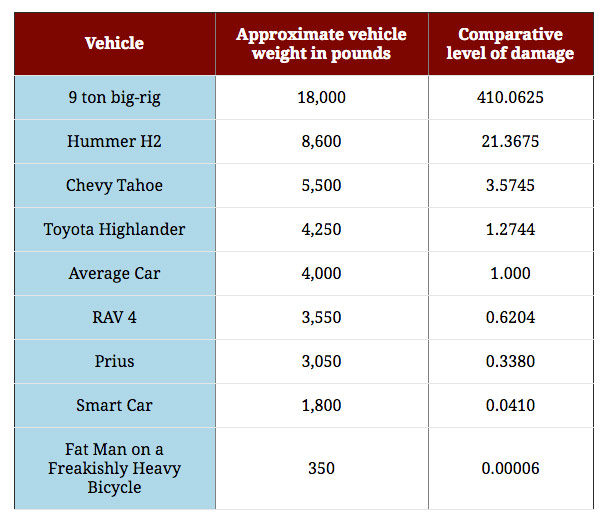

Most significant though, those pot holes? You’ll see a lot more, road damage happens at the fourth power of weight per axel. Simply put doubling the weight does 16x the damage to the road. The 2,261 kg Tesla is doing almost four times the damage to every road it drives down as our Volvo S60. This goes in reverse for smaller vehicles too. There’s a broader issue with the financial unsustainability of road infrastructure in general that deserves its own article at some point, but to keep this brief BEVs would make things significantly worse.

So 400 miles is fine for me, electric drivetrains sound cool and I have to pay a bit more road tax, why should I care? The point is to impress upon you just how tenuous the technical feasiblity of a BEV truly is. There’s no room for fallback, there’s no “we can cut that on the cheaper models”, the £25-30k BEVs sitting around the lot of your local dealership aren’t luxury cars, they are the Minimum Viable Product. The battery alone is half the material cost of the car and every other expensive feature is mandatory to support it.

The story for several years has been don’t worry, the affordable budget BEVs are coming soon. Scepticism towards that isn’t exactly new but it’s always been focused on the demand side of whether anyone actually wants to buy them en masse. Clearly that demand exists now with virtually all UK car buyers willing to go electric for the right price and the government planning to ban the sale of petrol and diesel cars by 2030. The real problem however is not with demand, but supply, specifically our magical Lithium-ion batteries.

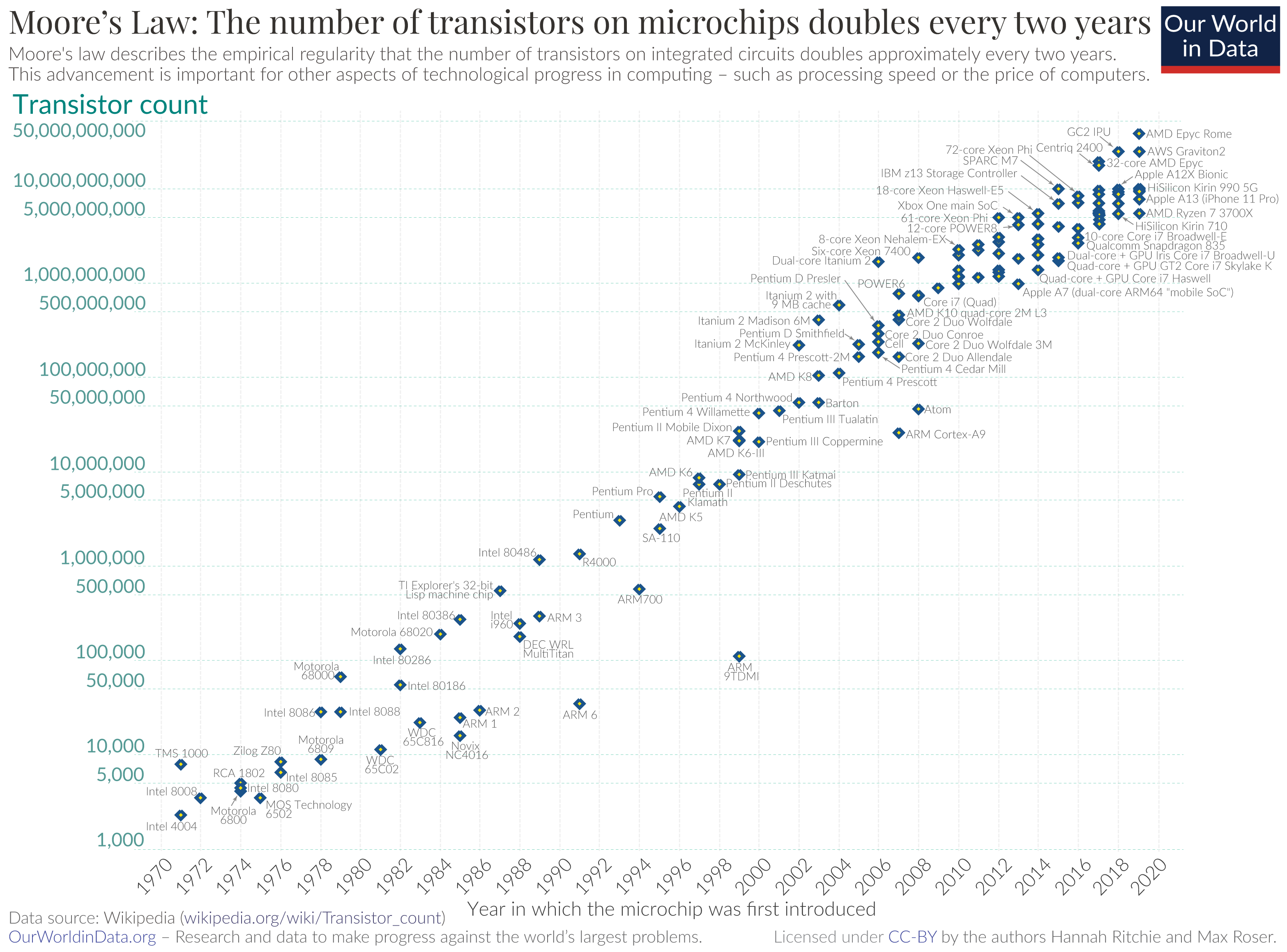

The reason I emphasised that Lithium-ion batteries were not a by-product of the mobile computing revolution but rather its primary driver was due to a similar trend in computing that many have falsely applied to battery technology. That trend is Moore’s Law:

Moore’s law is the observation that the number of transistors in an integrated circuit (IC) doubles about every two years. Moore’s law is an observation and projection of a historical trend. Rather than a law of physics, it is an empirical relationship linked to gains from experience in production. … In 1975, looking forward to the next decade, he revised the forecast to doubling every two years, a compound annual growth rate (CAGR) of 41%. While Moore did not use empirical evidence in forecasting that the historical trend would continue, his prediction held since 1975 and has since become known as a “law”.

Moore’s Law has had a fundamental effect on the development of computing. Simply put if you have an application for computers that isn’t practical at their current level of performance, you can just wait a few years and that issue solves itself. If it’s a particularly hard problem then you can just start working on it now, get funding, build the first iterations, and by the time you’re ready to launch the hardware will have caught up.

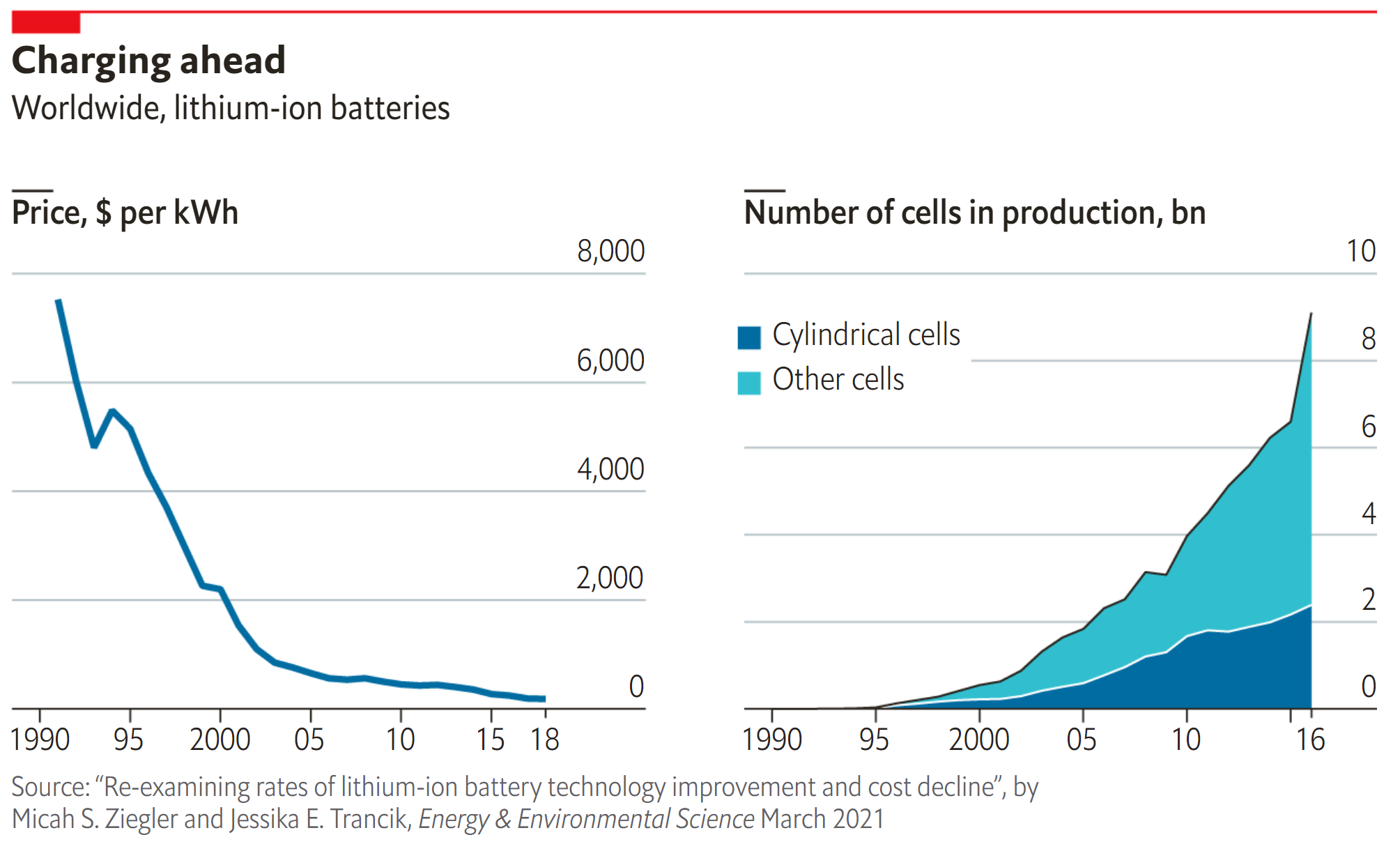

In the early 2000s it was noticed that the cost of Lithium-ion batteries was experiencing a similar trend with the price per KWh of storage capacity dropping by about 20% every year. It wasn’t as reliable, there wasn’t as much data, and it was based on completely different principles, but the close relationship with technology allowed technologists and investors to believe that just like Moore’s Law this trend could continue indefinitely into the future. Starting at $6,700/KWh in 1995 and dropping below $1000/KWh by 2010 it was enticing to believe. Famously in 2014 Elon Musk said he would be “disappointed if it took us 10 years to get to a $100/kWh pack.”.

This was of course embarassingly childish to believe, patently ridiculous to any human being on earth who conceives of the world beyond an Excel spreadsheet. While Moore’s Law relies merely on small consistent improvement in semiconductor fabrication, exponential price reduction of Lithium-ion batteries depends on us somehow managing to mine it out of the ground for exponentially cheaper amounts of money, and likewise for the Wh/kg energy density we discussed earlier to continue increasing, forever, despite a hard maximum of 460 Wh/kg imposed by the laws of physics and chemistry. This was never a promise based on insight from experts in the field, but instead a fairytale fabricated by tech grifters who looked at a line on a graph, decided the trend would continue into infinity, and used that as a compelling story for investment.

They looked at a trend of doing exponentially more with roughly the same materials through obvious compounding improvements in technology, and extrapolated that to doing roughly the same with exponentially more materials through “uh don’t worry about it, technology innit”.

Through 2020 and 2021 while most of the world was focused on the development and deployment of the COVID vaccine, this fantasy made contact with reality.

Lithium carbonate prices have also been steadily increasing over the past two years. In 2021, prices multiplied four- to five-fold, and continued to rise throughout 2022, nearly doubling between 1 January 2022 and 1 January 2023. At the beginning of 2023, lithium prices stood six times above their average over the 2015-2020 period. In contrast to nickel and lithium, manganese prices have been relatively stable. One reason for the increase in prices for lithium, nickel and cobalt was the insufficient supply compared to demand in 2021. Although nickel and cobalt supply surpassed demand in 2022, this was not the case for lithium, causing its price to rise more strongly over the year.

More information can be found regarding other rare earth minerals in the source, it’s a sobering read. The situation with Cobalt in particular is dire. Tesla is rapidly transitioning from Lithium-ion to Lithium Iron Phosphate (LiFePO) batteries for all but their flagship vehicles for exactly this reason out of pure necessity. LiFePO batteries have worse energy density by both weight and size, they’re still competitive and there are some real benefits with safety and lifespan, but they’re still a significant step back in the ways that truly matter and they still require massive quantities of Lithium.

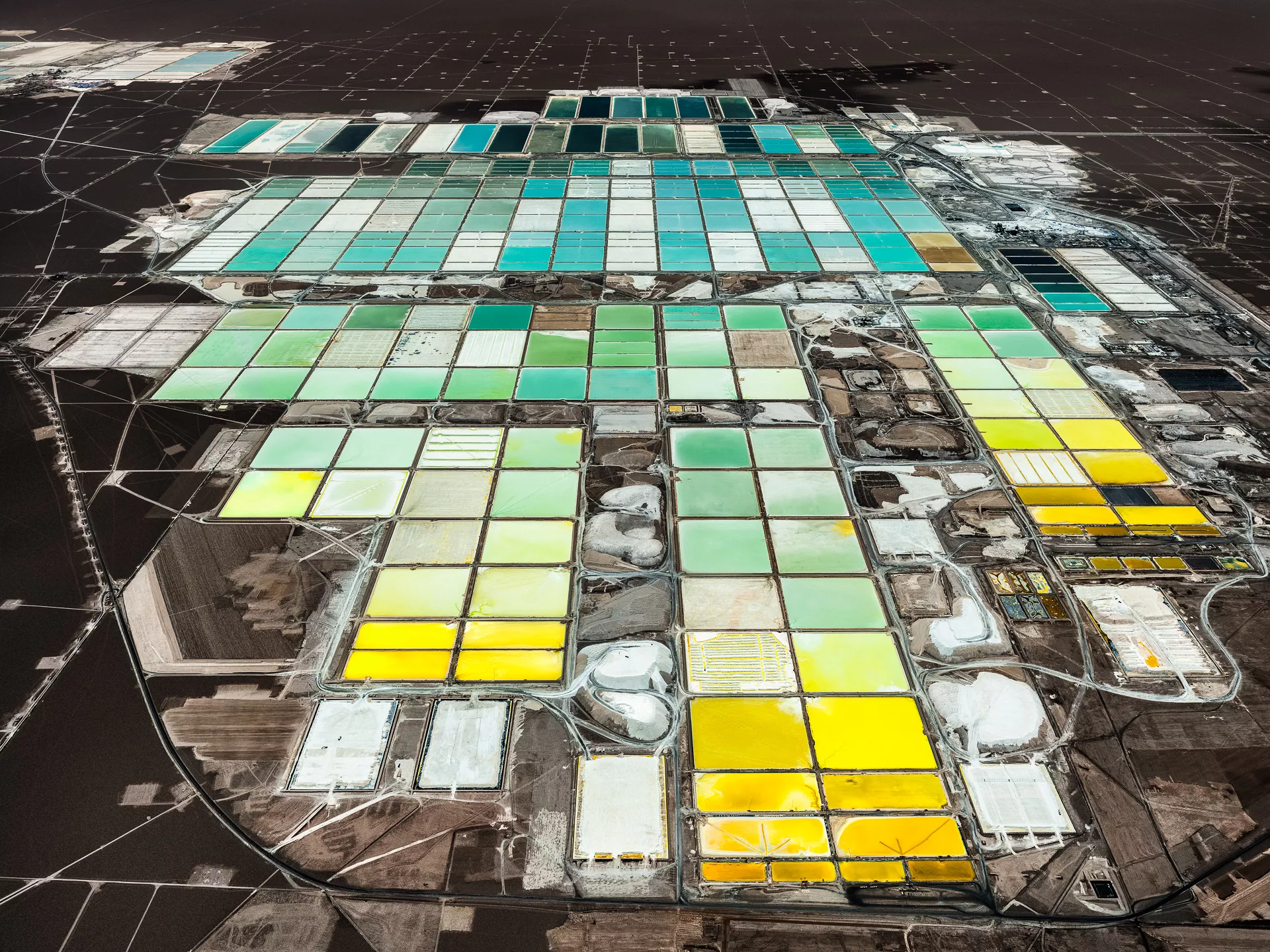

And this is where we come full circle, the reason you will never own an electric car is there’s just not enough Lithium.

In 2022 we reached a record high of 130,000 tons of Lithium Carbonate extraction, a 4.6x increase from 28,100 tons in 2010. Despite a trillion dollars of investment from corporations and governments alike over the last decade, this is barely 3% of the Lithium required to put a 400 mile Tesla battery in every new car sold the same year, a year in which car sales were already down by tens of millions off the back of the pandemic.

That Lithium isn’t just for electric cars either. Much of that Lithium goes into phones, laptops, wind and solar power storage, medical devices, highly specialised industrial chemicals and more. As we move to wind and solar power generation we’ll need to store more and more grid power to maintain supply, there are certainly ideas about what could be done and pumped hydro power is always a time tested option, but Lithium-ion batteries are right there and keeping the lights on will win a battle of priorties over the convenience of hauling a two-and-a-half ton crossover 6 miles to Big Tescos for a pint of milk.

It isn’t infinite either, current known reserves are only about 25 million tons so even if we could snap our fingers and magically teleport it from the ground to the factory, the automotive industry alone could run the world dry in less than 7 years.

Lithium-ion batteries wear out too, they’re heavily affected by temperature and being left mostly full or empty for long stretches of time, conditions they’ll commonly experience in a car. Real life studies on Tesla battery degredation shows that after 10 years they’ve lost almost 20% of their capacity. The average life of a car is 12 years. ICE vehicles they can be picked for parts to make other vehicles last much longer, but worst case scenario they’re mostly steel that’s easily scrapped. With the battery being almost half the material cost of a BEV and many advanced composite materials being used in their construction this is less true. We also can’t recycle much either, there is currently no process viable at scale for recycling Lithium-ion batteries into materials of high enough quality to make more batteries. There’s a lot of talk about recycling, there’s a lot of interest, but it’s been a decade and we’re no further forward. If cracked it’s a multi-trillion dollar industry, the fact no one has gotten anywhere speaks for itself.

So what’s going to happen? Simple. There are trillions of dollars riding on your continued belief that it’ll be fine, that this is all going to work out. The car industry got us into this mess, cars are the single largest source of greenhouse gas emissions, they knew about climate change as early as the 1950s and just like fossil fuel companies they spent eyewatering sums of money to make sure you didn’t. Now the cat’s out of the bag and they can’t deny it anymore. Their new strategy is to pretend they’re working on it, that they’re on it, and they’ve got you covered, and the Battery Electric Vehicle is their way to do that.

It doesn’t actually matter that we’ll destroy every road in the country trying to drive them. It doesn’t matter that refining Lithium is one of the most environmentally damaging industrial processes on the planet. It doesn’t matter that over its life a BEV is still responsible for at least 30% the emissions of a conventional car and therefore the entire story of a zero emissions car is a fairy tale. It doesn’t even matter that we’ll need to magically find thousands of times more Lithium and start digging it out of the ground 50 times faster.

All that matters is that you believe they’re coming for just one more financial quarter, and then another, and another. Because every year you do is another year they get to keep making eyewatering profits instead of us collectively, on a state level, starting to plan seriously for a world without cars. It can be done, there are massive benefits to building a world without them and it’s not even as expensive as you’d think. The average driver in the UK spends over £3500/year running their car. The automotive industry in the UK made £70 billion last year and the government pops another £13 billion/year on top of that from general taxation just on roads, there’s plenty money to go round if we want to do something else.

The UK government claims they’ll ban the sale of petrol and diesel cars by 2030. It might not be 2030, maybe it’ll be 2035, or 2040, but every year as we’re hit harder by the effects of climate change the political will to act will rise and eventually they’ll do it. When that happens it won’t be a world of electric cars we now know, what we’ll have is a world of transport poverty. In the same way we’ve been gaslit into seeing home ownership, energy and even food as luxuries, we’ll be gaslit into thinking the same of transportation. The cost of car ownership will increase dramatically, no investment will be made into alternative modes of transportation, and the tabloid ghouls will suggest that if you want to be able to get to work and see family then you should just cancel your Netflix subscription.

To avoid this we need to start investing in alternatives now. There’s no silver bullet but a healthy mixture of cycling infrastructure, electric micromobility, public transport, densification and just smarter city planning makes the car obsolete. We don’t even need to look outside the UK for proof, London tells the story. Only 42% of households in inner London have a car going down to 22.8% in the city, contrasted by an average of 78% of households in the UK as a whole. Most people don’t drive cars because they enjoy it, they drive because they’re the most convenient option, and that’s only the case because for 70 years there’s been practically zero investment into anything else. HS2 is the perfect example of this, it’s one of the most obvious and necessary infrastructure projects of the last century and yet the government has scaled it down again and again.

We also need to drastically improve transport culture within the UK. Public transport is seen as “the poor man’s option” outside of London, British drivers attitudes towards cyclists are notorious and I’ve written previously on the British media’s weird obsession with E-bikes. Even walking any significant distance is increasingly uncommon. Most of all we need to stop viewing transport as an individual problem.

They are casting their problems at society. And, you know, there’s no such thing as society. There are individual men and women and there are families. And no government can do anything except through people, and people must look after themselves first. It is our duty to look after ourselves and then, also, to look after our neighbours.

Margaret Thatcher, 1987

Well you know what Maggie? I love my family and my neighbours but I’ve never seen them build a road. If government can build roads then it can sure as hell put buses on them, prioritise bikes through them, and build train lines between them. We did it before, we can do it again.

.jpg)